Pneumatics, the branch of technology that deals with the mechanical properties of gases, plays a vital role in facility management, enhancing efficiency, safety, and cost-effectiveness across various industries. In facility management, pneumatic systems utilize compressed air to power tools and equipment, control processes, and automate operations, thus contributing to an optimized working environment. One of the key advantages of pneumatic systems is their ability to provide rapid and consistent motion, which is essential for tasks that require precision and speed, such as in manufacturing and assembly lines. Unlike hydraulic systems, which use liquids, pneumatics rely on gases, making them lighter and often easier to maintain. The simplicity of pneumatic systems also reduces the risk of leaks and associated hazards, which is crucial in facility management, where safety is a top priority. In facility maintenance, pneumatic tools such as drills, wrenches, and sanders have become indispensable. These tools often outperform their electric counterparts in terms of power-to-weight ratio, allowing for more efficient operation without compromising on performance.

Moreover, pneumatic tools typically require less maintenance, resulting in lower operational costs over time. Facilities that implement pneumatic systems can benefit from reduced downtime, as these tools can be easily swapped out and serviced without extensive training or specialized knowledge. For instance, pneumatig actuators can automate doors, gates, and other machinery, enhancing the ease of access and improving safety protocols by minimizing manual handling. Energy efficiency is another critical factor where pneumatics shine. Compressed air systems can be designed to optimize energy use by incorporating variable frequency drives, energy recovery systems, and advanced control systems. These technologies allow facility managers to monitor and control air consumption effectively, reducing waste and lowering energy bills. Moreover, by using energy-efficient compressors and regularly maintaining the system, facilities can further enhance the sustainability of their operations, aligning with broader environmental goals. This focus on energy management not only contributes to cost savings but also helps organizations meet regulatory requirements and corporate sustainability targets.

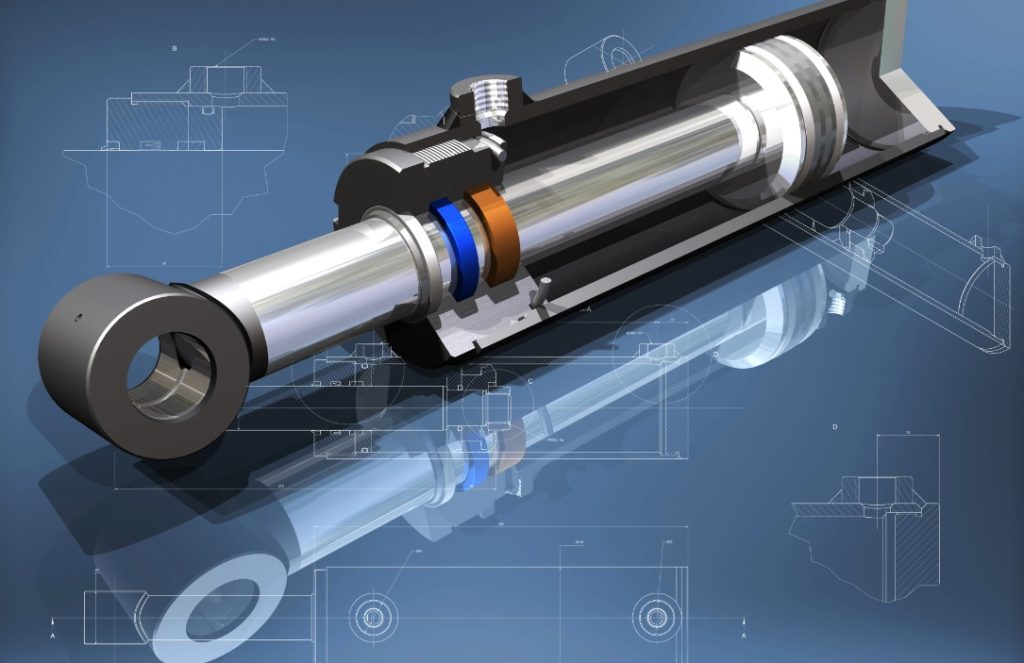

In addition to operational efficiency, pneumatics contributes significantly to the safety and comfort of facility environments. Pneumatic systems can be integrated with safety mechanisms such as pressure relief valves and automatic shut-off systems, ensuring that equipment operates within safe parameters. This integration minimizes the risk of accidents and injuries, promoting a safer workplace for all employees. Additionally, pneumatic systems are often quieter than electric or hydraulic systems, contributing to a more pleasant work environment by reducing noise pollution. This improvement in workplace ambiance can enhance employee satisfaction and productivity, further highlighting the multifaceted benefits of pneumatic cylinders manufacturer technology in facility management. The future of pneumatics in facility management appears promising, with advancements in smart technologies and automation paving the way for more sophisticated applications. The integration of IoT Internet of Things technology into pneumatic systems enables real-time monitoring and control, allowing facility managers to analyze data, predict maintenance needs, and optimize performance. This proactive approach not only extends the lifespan of equipment but also enhances operational efficiency and resource management.